Blog Entry 7 (Design Specifications & Prototyping)

This will be the last of my blog entries for now at least. It will be a summary of the journey of doing the product.

We first started off this journey by thinking of what chemical device we wanted to make. This is when we have to think of a pain point. I will be honest it was quite hard at first as we didn't really had anything that we wanted to change or improve. But eventually after some observations and questioning the people around us, we managed to come up with something.

Im short, i notice that at home my grandmother always eat an orange a day. The peels of the orange have always been thrown away and i felt that it was quite a waste. So we decide to make a device to reuse the peels by extracting fragrances from them. This later when on to extending to not just orange peels but other citrus skin peels.

Then we went on to do the literature review. We researched on many things. Through this i found out many things such as not only do i feel that there is a wastage of the peels at home, around the world there are tonnes of peels being thrown away a year also. It is also after doing the review that we extended the device to all citrus fruit skin also as we found out that the component that was producing the smell called d-limonene is actually present in most citrus fruit.

Afterwards we did SCAMPER, to see if we can still come up with different variations of our design to improve it. We came up with 5 of it, and use feasibility table and COW's Matrix to determine what was the best idea to implemnent. Which we eventually got as adding rubber seals to the second layer lid to make it airtight. Of course, this is just a brief summary of what happen. To see more details, you can look at my previous blog entries.

Our device consist of 2 layers.

1st layer compartment: Grater and mechanical dryer

Where there is a grater in that layer of the container, to grate the citrus skin to smaller pieces. It is also the place where the grated citrus skin is left to dry. There will be a fan in that compartment (mechanical dryer) to speed up the drying process by promoting air circulation .

2nd layer compartment: Air tight container to contain the mixture of ethanol and citrus skin peels. This is to extract the d-limonene (fragrance) out from the citrus skin.

Sketch

There is 2 process for this device. Below is the operating principle and mechanism.

We also did sustainable design by changing the material from normal plastic to using recycled HDPE, that is also ethanol resistant.

Next we move on to the specification table where we stated the properties of the design such as weight, operation time etc. As shown below.

The last thing that we did was to construct a cardboard prototype of our device.

To make the containers, we cut out the cardboard like this.

We cut out 2 sets as there are 2 layers. Then make a shallow slid along the center square so that it can be folded like an L brace. For the bottom one it will look like this.

For the top layer, before folding it we had to cut out the holes for the fan and the vent, like this.

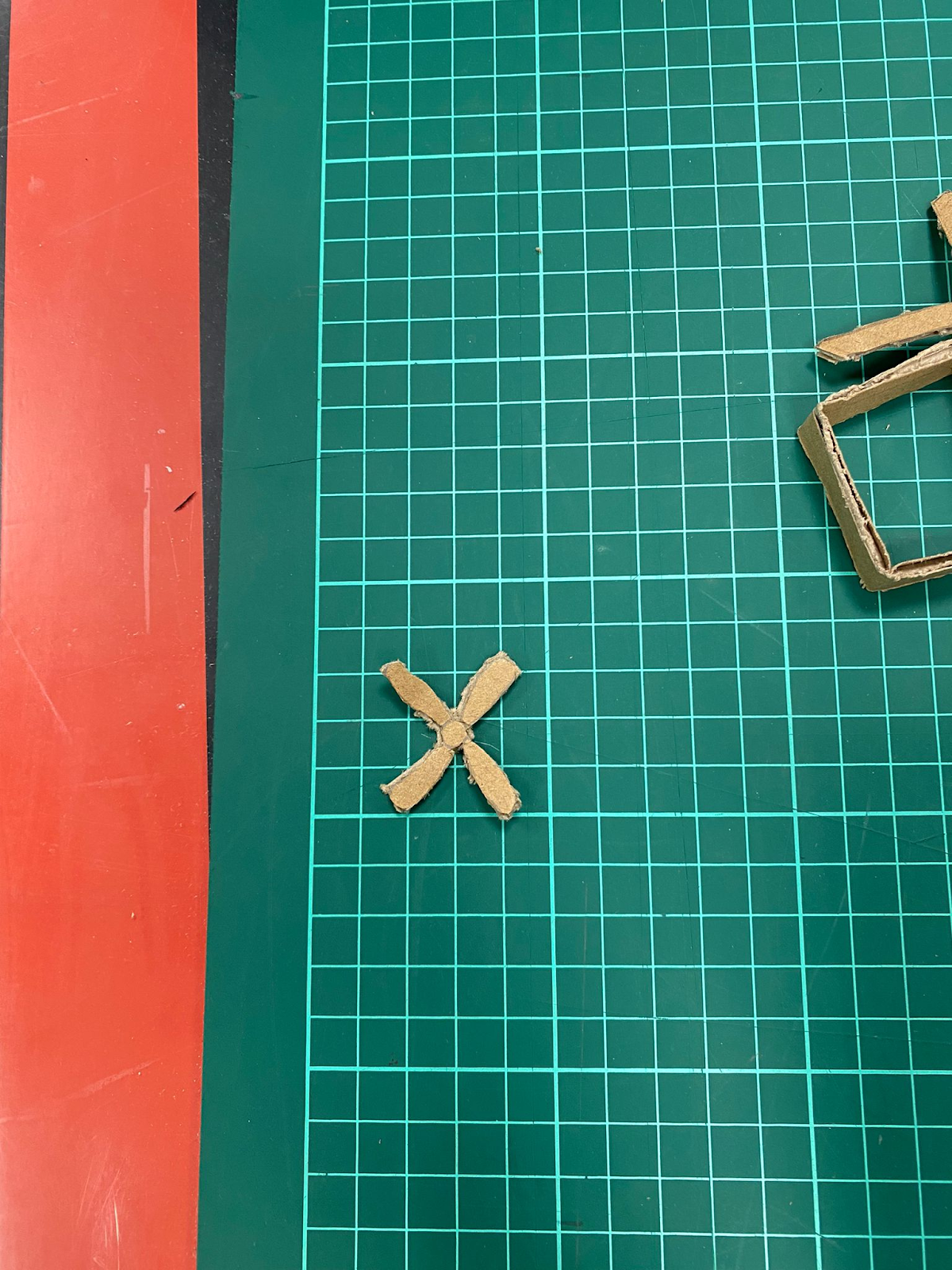

Then we cut out the shape of the fan and its back cover.

We glued the x-shaped back to the rectangular hollow box. This will be the back cover of the fan. Then using a brass fastener, we connected the fan and the back cobrr together. Afteerwards, the entire thing wad glued to the first layer cutboard before it was fold into a container box shape like this:

We than cut out 2 square cardboard that will be the lid and the grater respectively.

Comments

Post a Comment