We were taught about Operating Principle and Mechanism this lesson. There are two definitions for mechanism.

In chemistry, Mechanism is the fundamental chemical processes involved in or responsible for an action, reaction or other natural phenomenon.

In Engineering however, Mechanism refers to the combination of rigid or resistant bodies, formed and connected so that they move with definite relative motions with respect to one another. More simply, it is something that transforms forces and movement into a desired set of output forces and movement.

We are going to be using the definition for engineering as this is chemical engineering after all.

An example of a essential mechanism in functional prototypes are ratchets. They lock in one direction, allowing them to tighten without fear of literally "going backward." Example: Cable ties.

After learning about this, we were tasked to design a ping pong ball launcher with the following guiding questions:

- What is the mechanism that shoots the ping pong ball?

- How are the ping pong balls reloaded after one is fired off?

The device should also:

• The device should be able to hold at least 5 ping pong balls.

• Device should propel the ball with stored energy.

• Mechanism can be fully automatic, semi automatic or fully manual.

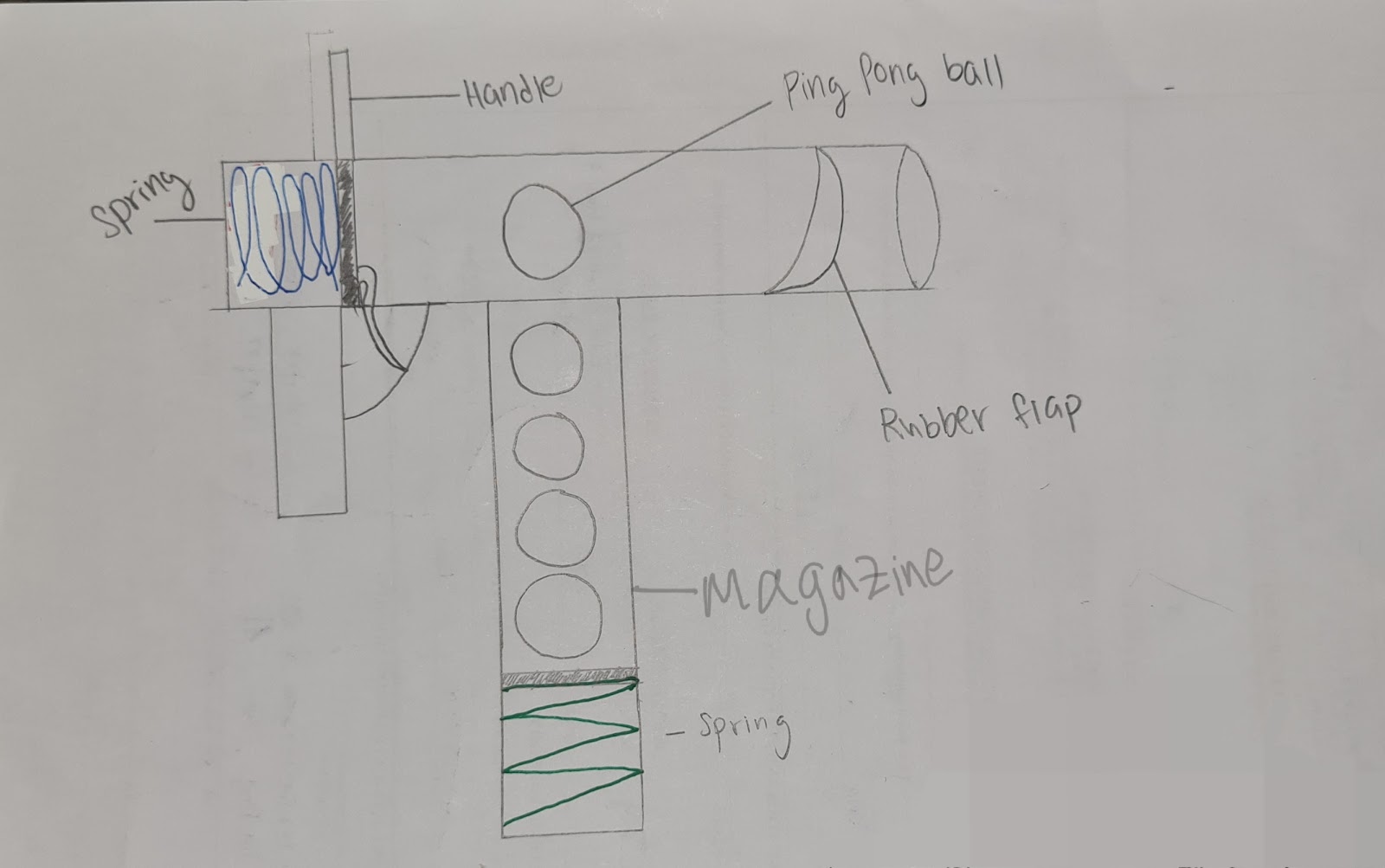

Below is the design we came up with.

Ping Pong Ball Launcher

|

Propulsion Principle The launcher uses a spring as the energy storage mechanism to propel the ping pong ball. User will have to manually pull back the handle that is connected to the spring to compress the spring. The trigger will then hold the compressed spring in place. When the trigger is pulled, it will lay flat with the barrel which will allow the spring to release and propel the ping pong ball out.

There is a rubber flap at the end of the barrel also. This is to prevent the balls from falling out. Since the rubber flap is flexible, when the ping pong ball is propel out, the force of it will be enough for one end of the flap to bend and give way for the ball to exit. The rubber flap will then bend back again after the ball exits.

Ball Loading There is a compressed spring at the end of the magazine. It is kept compressed by the weight of the ping pong ball. As the balls propel outwards, the weight decreases which means the spring can unwind more. This means that the ping pong ball will automatically be pushed upward by the spring at the bottom after one ball gets propelled out.

|

Sketch

Before pulling the trigger

After pulling the trigger

|

Practical 4

In this practical, we were tasked to design and make a Marble run machine out of cardboard as a team in 2.5 hours.

Requirements are:

• The cardboard structure must incorporates one manually operated mechanism.

• The structure must be able to keep a marble (average diameter: 22 mm) in continuous motion for at least 30 seconds

• The structure should not be more than 100cm x 100cm x 100cm

• Structure should be made predominantly of corrugated cardboard

Our group decided to use the pulley system as a lift to pull the marble up. For the pathway, we decided to add obstruction in to slow down the marble so that it can hit the 30 seconds mark. We didn’t really have a sketch for it. We just decided to wing it. 😝😝😝

We constructed the tower and box for the pulley system first. This is so that we can get a gauge of how tall our entire structure will be. We just cut out a long piece of cardboard and make an L brace to get it to fold. For aesthetics purposes also we cut out little windows at tower.

Like this:

We attached a stick to the top so that it can act as a sort of pivot to help us to pull the pulley box up.

The box to hold the marble during the pulley operation also included a ramp so that the marble can slide off more easily.

Next we make the pathway for the marble to run. The pathway is made the same way as the tower just that the width of the cardboard is smaller. We made 2 of those. We then made little obstructions to be placed on the pathway.

We made obstructions that consisted of using

- Flanges

- Tabs

- Inserts

- Slot and Tab

as attachments.

Then we attached those obstructions to the pathways. Other then the slot and tab the rest were either hot glue on or paste using a tape. Here is a picture doing it:

We then make a curved structure. This is so we can change the direction of how the pathway is being placed at so that the marble can change direction and roll back to the pulley box.

We then attached the pathway and the curved structure together by using either brass fasteners or cable ties.

We than had to make supports for the pathway. There is no way the pathway can be suspended in the air without supports that would have been a miracle and just plainly defying gravity. We make two types of supports, one shaped like an hollow triangle and one using a flange.

The one being hold by the white gloved hand is the hollow triangle support.

After making all the parts we can finally put it all together. It will look like this after we combined everything.

Here is a video of it in operation.

Reflection

This actually isn't the first time that we get to use cardboard to make something. In fact, in blog entry 3, you will be able to see that the group made a cardboard vending machine using the different type of joinery and attachment also. So because i had experience, I wasn't really that nervous or worried about making the marble run machine.

However, on the actual day of making this machine itself, I realized I forget some of the ways to make the cardboard attachments😟. I had to get some help from my groupmates to jot my memory. Luckily, i was still able to remember after some prompting.

I am glad that I had another chance to work with cardboard again. This helps me practice more. And like they say: Practice Make Perfect.

Comments

Post a Comment